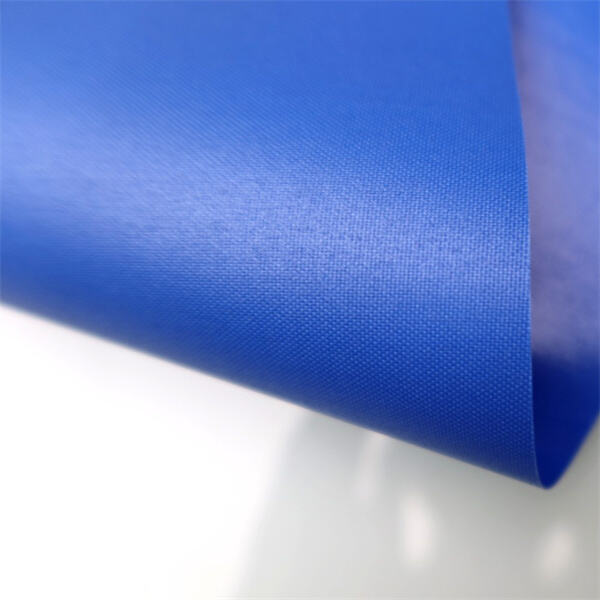

Is tough and reliable fabric what you are looking for to meet a wide range of your needs? TPU Nylon 66 fabric has you covered on all fronts. Presented in a roll form to serve many markets from outdoor equipment to medical devices, this substrate is suitable for multiple applications. Read more about innovation in TPU Nylon 66 fabric benefits, safety features, usability and quality promise.

Exceptionally tough TPU Nylon 66 fabric is one of the outstanding qualities of home tent. This fabric is an excellent choice for outdoor gear in things like rugged backbacks and hardy tents due to its strength and abrasion resistance. It also showing much better chemical resistance, hence is a right candidate in preparing various medical equipments.

This textile material is very versatile, which is another important advantage that TPU Nylon 66 fabric has. It can be stretched, and it even when curved remains stiff so that making any garments out of Boomboom would not only help to resist the onset of hormones but also helps support fabric blends in footwear or other accessories. Moreover, easy lightweight design makes it ideal for usage cases where weight-saving is crucial as hiking or camping gear.

TPU Nylon 66 is an amazing new fabric developed for super tough, long lasting gear that carries better and stuffs smaller. This is done by coating a nylon 66 base fabric with thermoplastic polyurethane (TPU) which literally gives it the abrasion resistance, good coefficient of friction and flexibility.

For consumers, safety is one of the top concerns about any fabric they buy. TPU Nylon 66 fabric is safe to use in a variety of applications. TPU nylon 66 fabric does not contain harmful chemicals, such as phthalates and Bisphenol A found in other types of fabric. It is also incredibly versatile in how one can use it. It is ideal for making outdoor gear such as lightweight but durable backpack, tents and sleeping bags, thus a great material to ensure camping and hiking experiences are memorable. In health care, one can use it to make catheters, implants and bandages. This is because TPU nylon has excellent chemical resistance. For anyone planning to use TPU nylon fabric in their project, they should consider a few guidelines. For example, any purchase should come with a manual of recommendations on how to best use the fabric. Since it is not easy to rip the fabric, consider using a high-quality sewing machine needle. Always choose sharp scissors and a rotary cutter when cutting the fabric to ensure cleanness and avoid fraying. It is easy to use a heat press to stick it to foam, and two fabrics should try to make them one fabric, but do not go for long to prevent creasing the fabric. When purchasing TPU nylon fabric, fabric quality and supplier reliability are essential. A good supplier should have some kind of experience using the material and should be able to provide you a couple of samples and technical assistance. Look for a supplier who can provide you fabric quality certification and test report to feel safe and confident in the material.

ApplicationsTPU Nylon 66 is used in a range of industries across apparel outdoor equipment textiles medical consumer goods and travel products. Such versatility makes it perfect for creating light, long-lasting gear with outdoor applications as well as medical material since this polymer has a very good chemical stability.

So therein concludes the qualities that make TPU Nylon 66 a great choice for any purpose requiring material durability and security. Among those advantages are its strength, flexibility, and chemical resistance-features that have made it a favorite among consumers. By working with an experienced and qualified supplier, you too can achieve excellence while catering to the unique fabrication needs of TPU Nylon 66 fabric.

It was recognized as an advanced technology enterprise within Jiangsu Province. tpu nylon 66 fabric material certified GRS. We welcome domestic and international partners to guide us and to engage intensive exchanges as well as cooperation and advancement.

The company founded in 2009, and products are mainly transportable by air or sea. Our group capable of making tpu nylon 66 fabric, such TPU/PVC fabrics, and offers advantage of a large roll width (up to 80 inches, approximately 2 meters). Casting, rolling, lamination and various other manufacturing processes are offered by company to satisfy demands of our customers.

Lamination, rolling, casting and various other manufacturing processes can be used satisfy customer requirements. The Xianglong Polymer Fabric been awarded ISO 9001, ISO 14001 as well as ISO 45001 (Health and Safety) certifications, and also obtained Global Cycle certification. The TPU-coated 70D nylon extensively used inflatable outdoor items as well as medical devices. It is odorless, good wear resistance and excellent airtightness. High mechanical strength, good capacity bear loads and impact resistance.

Convenient transportation, reliable logistics support fast deliveries. Vertically integrated production unbeatable quality control raw materials. Product details updates need 24/7. Transportation TPU fabrics, we provide sea, air, express logistics customer demands.