How to Find a Good PVC Coated Factory?

For example, you are looking for PVC coated factory supplying fences, cables and hoses etc., or only to find some good quality of the best pvc coated. PVC, Polyvinyl Chloride is a flexible plastic polymer that has been widely used in many industries to make applications because of its life and flexibility. Advantages : Pvc coated products are more durable as you can see in photos the top cover of pVC giving enhancing look and longer life. Unfortunately, when it comes to PVC coated systems they are not all built the same which is why we recommend evaluating a number of options before you decide on where to place your business. In this article, we give you a fit on how to know the best PVC coated factory and its benefits.

Benefits of PVC Coated Items

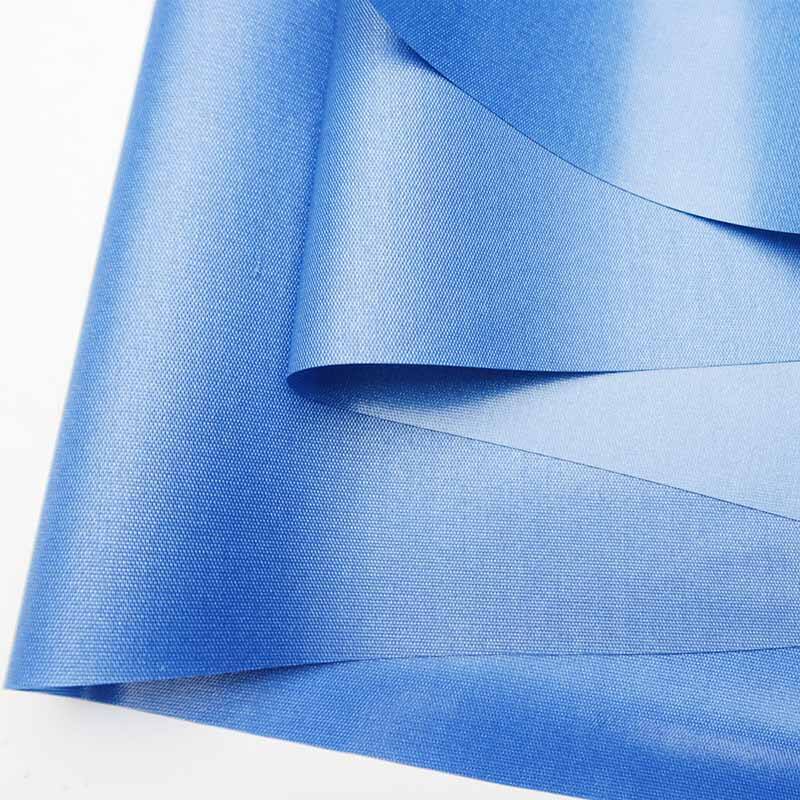

Non-coated vs PVC coated: The benefits of products with a coating How does its PVC coating do that you might wonder, well first and foremost it gives you a strong protective layer against physical, chemical and environmental damage. This means that PVC coated products are resistant to corrosion, weathering, ultraviolet and sunlight exposure, water absorption & chemicals as well abrasion hence can be used both indoors and outdoors. The PVC coating also provides product safety features by adding insulation, fire retardancy and non-slip qualities. In addition, providing the products with color more attractive to aesthetics and textural effects are done through matt-glitter or gloss treatment. PVC coated products and systems wrap indefinite maintenance, easy to clean with the usual fluent cleaner and waterway followed by time-examining or steam disinfectant (if ascribe), therefore saving period, money and might appliances.

PVC Coating for the Future's Wood [Infographic]

It the past, many believe PVC coating technology is a small area without much research but its rapid development has become an important extensively-used liquid coatings. Nowadays, there are several PVC coating methods such as different method, material and equipment to accomplish the performance level. One such popular method is dip coating, which consists of dipping the product into a PVC liquid tank and curing it through heat, radiation or air. Spray coating is a high-speed process that applies liquid PVC to the surface of the product and then cures with heat or light. Extrusion coating is a continuous process in which the product is coated with molten PVC at during manufacturing. Additionally, PVC coatings are customizable to thicknesses, hardness values (shore A), bonding or antimicrobial properties.

Safety in PVC Coated Products

Safety is a primary focus when it comes to PVC-coated products because they are used so often in applications such as electrical wiring, medical devices and food packaging. Therefore, choosing the PVC coated factory that meets all local safety standards and regulations is very important. For example, the PVC material should be eco-friendly not contain harmful substances such as lead, cadmium and concentration of phthalates low toxicity flammability. The factory needs to offer proper ventilation, protection gear and training for workers handling PVC materials and machinery. They also should have stringent testing, certification and inspection protocols in place to guarantee the safety quality of PVC coated products before they reach consumers.

PVC Coated Products Usage and Application

Various industries use PVC coated products, such as agriculture, construction, transportation healthcare sports and leisure. These PVC coated products can be found in applications ranging from wire mesh fences for farms, gardens and residential spaces to steel wire ropes used for lifting, anchoring or hoisting; flexible hoses associated with irrigation, drainage and ventilation systems; pipes for plumbing electrical & HVAC work among many other uses. PVC coated products need to be used in the proper way so as not misactuyally wear them down quickly, just using a manufacturer guidelines and recommendations. This means not overrating the products, or using them out of their temperature range and avoiding cuts by sharp objects, immersion in chemicals that may degrade the PVC layer; dry storage with moderate temperatures are a must to prevent any degradation until you need it.

The best PVC Coating Factory inService and Quality

The to consider while buyiing is - who much a plants I. service and he best PVC coated_FACTORY A good PVC coated factory will provide:

Responsive and efficient modes of communication - Email, phone or Chat for any queries/problem prior to examination.

Customized solutions, based on specific needs in terms of size, shape or color and branding

Prices are competitive and reflect the value of quality PVC Coated products.

Delivered on time that fits your timeframe and cut off dates.

Personalized payment plans to fit your budget and needs.

Making sure the products in PVC coated are comprehensively quality assured with testing, certification and warranties.

Good Reputation And Customer Feedback With Consistent Satisfaction Provided By The PVC Coated Factory

To sum up, when it comes to seeking the top PVC coated factory, one should take under deliberation all these considerations on account of advantages, innovation development security and convenience application servicing quality assortment products. According to the recommendations, based on that you are able to carry out good decision for your business, project or personal needs. PVC coated products offers not only performance but also aesthetic, durability and safety. Some Rig mats to choose from: Read more Choosing the right PVC coated factory can make a big difference in terms of performance and longevity, ensuring that it is effective for your needs.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

BN

BN

IG

IG