How to Choose a High-Quality Nylon TPU Manufacturer

Nylon thermoplastic polyurethane (TPU): A unique and flexible product material that allows the item to resist absorptions. It is good for a lot of industries, fashion etc So choosing a right nylon TPU factory is crucial for your products with high quality. Here are a few key considerations to keep in mind when choosing the factory best for you.

All Things You Need to Consider

Quality Control: Good factories will have solid QC checks in place to ensure product isn't made bad.

Show customization: No factory can do some special TPU blend for you. (This one is important)

Make production: It needs to be sure the factory can run that number of products.

Level of expertise: The factory is assumed to be an expert at producing and troubleshooting any issue.

Qualities of a Good Factory

Characteristics of a Great Factory

Transparency - they should be telling you everything about how a product is made.

Innovation - That they should constantly be trying new things and adopting the most modern technology.

The People: It is said that, the factory of which many happy customers are already maintained means a lot.

How to Find the Right Factory

So, to source right factory for you and your business;Steps (What do you need), Budget(How much it costs) Time I have(Time of delivery.... Trade shows - Association groups direct to consumer Personal references

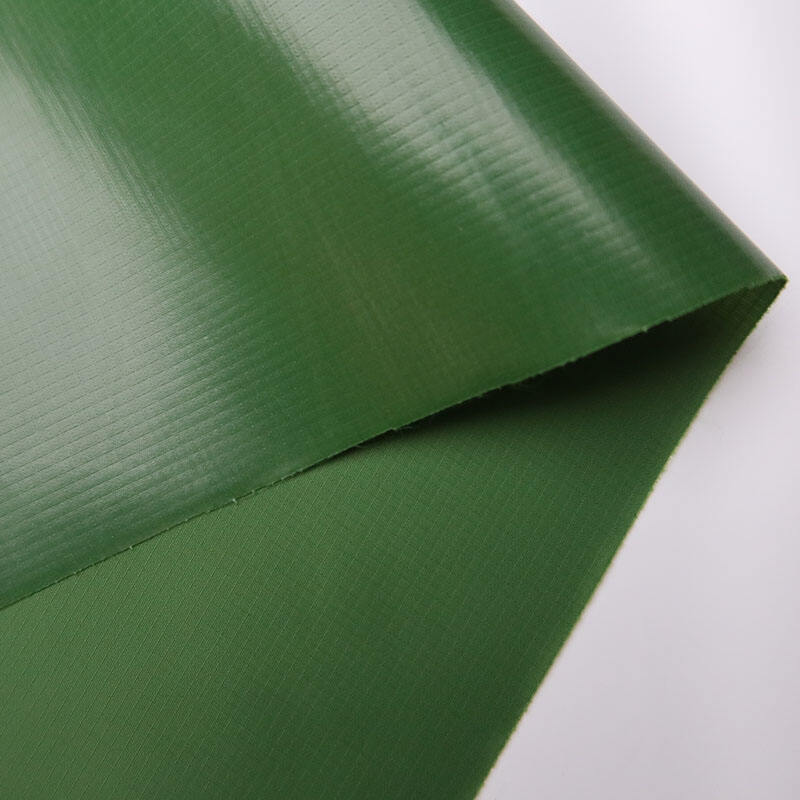

Good Factory - Imagen

A good factory is equipped with modern machines, a clear and clean space for production process. And the products supply management method must be able to properly control the order. They are productive which helps to reduce waste. They are also adhere to safety and environmental regulations.

Eco-Friendly Factories

These days, being eco-friendly is a crucial factor in factories. Meaning they use recycled materials, produce in a way where it does no damage to the environment and adhere exceedingly well to sectorial international green rules. Materials like hemp are used in some orient - been factories.

Selecting The Ideal Nylon TPU Factory Make sure to scan through the different sections of The Factory before finding a one that suits your need. When the factory cooperates with nylon TPU at a discount and produces excellent products, it has to be successful.

Key Factors to Consider Selecting a Superior Nylon TPU producer

Whether for fashion or automotive - nylon thermoplastic polyurethane (TPU) is a go-to solution to create forward-thinking and sustainable products. A popular choice in applications where durability and malleability are vital, TPE has become a go-to material for combining the best of rubber (rubber grips) with plastic. Remember, choosing the right nylon TPU factory is perhaps the most important step to make sure your product is of excellent quality. This article will explore the finer points and unique attributes of industry-leading manufacturers.

Key Finding out Factors on Top Nylon TPU Manufacturer

Key factors for choosing the right nylon TPU factory

Quality Control: Select factories that has stringent quality control standards in place, i.e. ISO 9001 and can assure you of continuity good qualities requirements from CIF to FOB with a difference on labor wage increment.

The final pillar is customization of TPU blends by the manufacturer to meet specific performance requirements. Choosing a manufacturer that offers custom solutions can make your product unique.

Volume: Confirm the factory is able to handle your volume - large-scale runs for manufacturing, short batch production (for prototyping).

Technical Skills: The manufacturing capability of the facility along with its ability to conduct research and development (R&D) in areas related to product innovation or solving issues is paramount for the biopharmaceutical sector.

Characteristics of a Reliable Nylon TPU Manufacturer

A reputable nylon tpu manufacturer should have the following qualities:

Open communication about materials, processes and cost encourages transparency.

Unique Process: The factory is focused on investing in newer technologies / material development to stay ahead of the curve.

Mammongoose Portfolio: Thousands of clients have testified that the factory is capable and reliable.

The Nylon TPU Manufacturing Landscape

The complexities in manufacturing nylon TPU have made it necessary for players to take a proper approach. The other thing to do is defining your individual needs, those material properties that the product must meet, price limit and also desirable project times. Attending trade shows, participating on industry forums and getting references from your network can help to identify the potential manufacturing partners

Take a Look Inside the Leading Nylon TPU Manufacturing Facilities

State-of-the-art machinery, cleanroom environments designed for sensitive applications and a streamlined supply chain make production facilities best in class. These factories are designed to minimize wastage and for higher productivity based on the principles of lean manufacturing. Periodic audits - and environmental controls resulting from these regulations ensure compliance to safety & sustainability standards.

GRN 5 ways for Environmentally-Friendly Nylon TPU Factory Identification Photo by Alex Azabache on Unsplash

Today, sustainability is not an option but a requirement. Environmentally friendly nylon TPU factories are dedicated to recycle, reducing the carbon dioxide concentration in production operation and comply with international standards for ecological testing of extracted chemical compounds R.E.A.C.H. & RoHS Another option is selecting factories with bio-based TPUs, which are made from renewable feedstock instead of non-renewable.

Ultimately, you have to go through a detailed scrutiny regarding the steps in finding a sound nylon TPU factory. Each point from their quality assurance protocols, to customization capabilities and even sustainable footprint all play a part in the success of your latest project. Working with people who believe in what you do, and appreciate how to get things done at your level of quality is the first step towards a durable relationship for producing nylon TPU on demand.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

BN

BN