How to Select The Best Manufacturer Of TPU Coated Fabric in a Comprehensive Guide

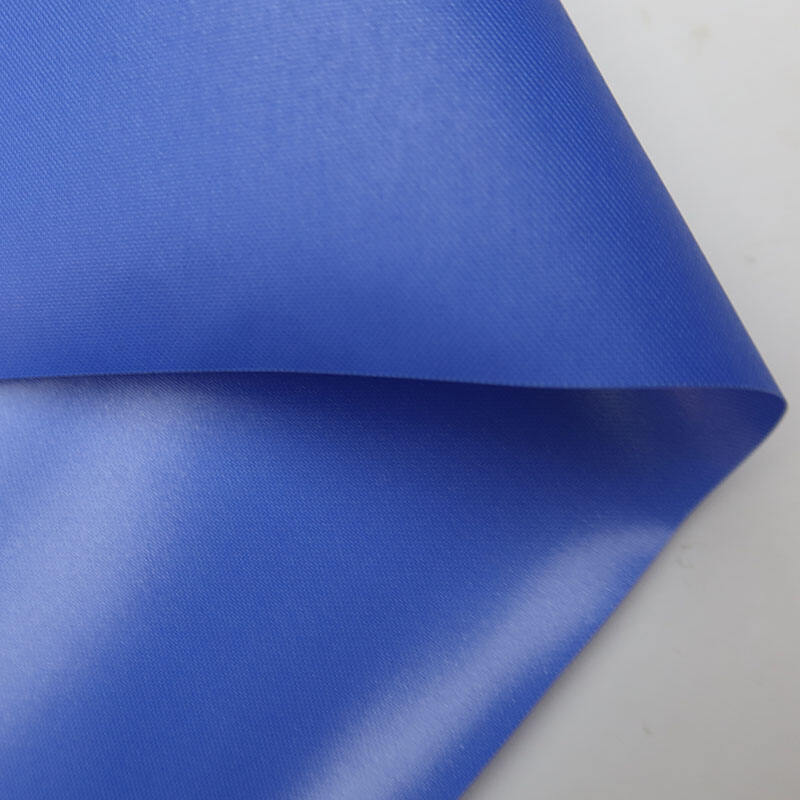

Choosing a good TPU coated fabrics this seems to be very difficult when manufacturers are in front of you. Technical textiles have to fulfill the demanding requirements across a variety of industries and as such, quality, innovation. sustainability etc. intertwine fragrantly in this complex multifaceted land scape resulting products that must last long and perform under grilling circumstances both processing wise (assembly line) or per desired attributes over their life time till usage sinteniity constrains are met!) We speak about Technical textile...normalized! Thermoplastic Polyurethane (TPU) coatings are tough, flexible polymers that resist a number of environmental conditions and have seen widespread use within the outdoor equipment market as well as in medical device applications and automotive upholstery. Availability from a bazillion manufacturers is one challenge to solve, but it can be even harder to end up with the right partner for your specific needs and requirements. As we embark on a deep dive into the key considerations when assessing TPU coated fabric producers, this article will serve as your all-embracing guide uncovering various aspects that businesses should look at to develop their supply chain strategies and drive excellence.

Key Factors to Consider When Choosing TPU Coated Fabric Suppliers

Focus on Quality Checks and Certifications

You need to begin with the evaluation and make sure that reflects on how trustworthy they are in terms of commitment to quality control from their manufacturer. Certifications such as ISO 9001 for compliance with the international standards of quality management You should also need to ask the certifications that are industry-specific, as like OEKO-TEX for textile safety and REACH compliance if you use chemicals in fabrics. These certifications basically let you know that a manufacturer is serious about making safe and reliable products.

Performance and customization

One of the benefits is that TPU coatings can be made to meet very specific performance objectives: from waterproofing, breathability and abrasion resistance among others. For a formulator, nothing is more critical than working with an experienced manufacturer who knows the characteristics of these raw materials and can provide custom formulations based on unique requirements. Have in-depth conversations concerning project requirements to evaluate their sense of problem-solving and understand if they will be able provide solutions that cater to your explicit needs.

Evaluating Production Capabilities and Lead Times

You need to know the production capacity of a manufacturer, which is important for deadline and abilitity in changing requirements. Consider the capacity to meet high volumes of parts without sacrificing quality or timely deliveries. Just as important is their history of lead time control, especially within verticals in which quick product launches are a requirement for success.

Sustainability efforts will be a consistent trend

It is important to choose a TPU coated fabric manufacturer, who use environmentally friendly methods as well as non-polluting production lines in the current world of conscious environmental market. Brush up on their use of green materials, recycled processes or energy saving manufacturing. Partnering with a green manufacturer can improve brand image and attract eco-friendly customers.

Ethical Sourcing & Labor Practices

Make sure that the manufacturer you choose follows responsible sourcing and fair labor practices. This includes the responsible sourcing of raw materials, elimination child or forced labor and safety for workers. The practice will request audits or third-party certifications for social responsibility, as SA8000.

Innovation and Research & Development Commendation

Partner with a manufacturer that researches and develops. The continuous innovation of the TPU technology enables improved performance, new applications and environmentally-friendly solutions. Any modern manufacturer will provide more than just an innovative product, but also the means to future-proof your packages for upcoming industry trends and regulatory changes.

Efficient Communication and Customer Care

Any partnership, no matter how big or small it is,must have clear communication at the core of their foundation. Initial touch point with the manufacturer - have they been responsive and are their interactions transparent. A manufacturer that places an importance on keeping in touch and assigns dedicated account management will always help your working relationship go smoother and should there be any teething problems, they can be ironed out pretty quickly.

Financial Security & Sustainability

Final decision is done by process the financial health and history of manufacturer. Strong Companies are Stable : A company that is strong with good financials, means survivability amidst turbulence and a likely hood to pull through economic ebbs without compromising on hospitality supply. Look for how long they have been in operations, customer feedbacks and if their financial reports are made available (to understand trustworthiness).

In summary, the selection of a TPU coated fabric manufacturer requires comprehensive assessment in many aspects. Taking a closer look at quality control, customization capabilities, production efficiency and speed to market, sustainability principles in the company's genetics reputation for ethical standards alongside with innovation,independent communications schedule or financial stability are sources of future competences needed that will help differentiate prospective partners from one another while ensuring they can deliver higher capacity as required. Keep in mind, the choices you make today will set the foundation for a productive relationship that can last.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

BN

BN

IG

IG